sales@maximius.co.in - GST NO. : 36AAXFM0059J1ZS

- Send Email

Silo Accessories

Leading Manufacturers, Exporters and Wholesaler of Cement Silo Accessories and Unbalance Vibratory Motors from Hyderabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Manufacturer | Maximius |

| Type | Accessories |

| Material | Various Materials |

| Application | Designed For Dust-free, Safe, And Efficient Silo Operations |

Product Discription:

Maximius supplies a complete range of Screw Conveyors and Silo Accessories designed for dust-free, safe, and efficient silo operations. Our Screw Conveyors handle powders like cement, fly ash, micro silica, GGBS, lime, and slag, with capacities from 6m³/hr to 100m³/hr. Key silo accessories include:

Pressure Relief Valves (VCP): Protect silos by instantly controlling excess pressure or vacuum.

Silo Bottom Butterfly Valves (VFS): Made with high-pressure cast semi-bodies, durable seals, and smooth flow control.

Silo Aeration Systems (VB, VBE, VBI, VBM): Combine air circulation with gentle vibration for reliable discharge.

Silo Venting Filters: Cylindrical collectors with POLYPLEAT filter elements, specially designed for cement.

Bridge Breakers: Ensure uninterrupted material flow by breaking arches without stressing the silo.

Bin & Pneumatic Vibrators: Wide range including roller, piston, ball, turbine, air hammer, electric types for silos, hoppers, chutes, and trucks.

Applications span silos, hoppers, pipelines, and trucks, delivering safety, reliability, high performance, and global availability.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Unbalance Vibratory Motors |

| Usage | Vibration Feeder Technology And Bulk Material Handling |

| Max Operating Torque | 0.1 Kg.cm To 2,763 Kg.cm |

| Max Force | 119 KN |

| Vibration Types | Linear, Circular, Elliptical |

| Arrangements | Linear Motion,Circular Motion,Elliptical Motion |

| Frequency | 50/60 Hz |

| Manufacturer | Maximius |

Product Discription:

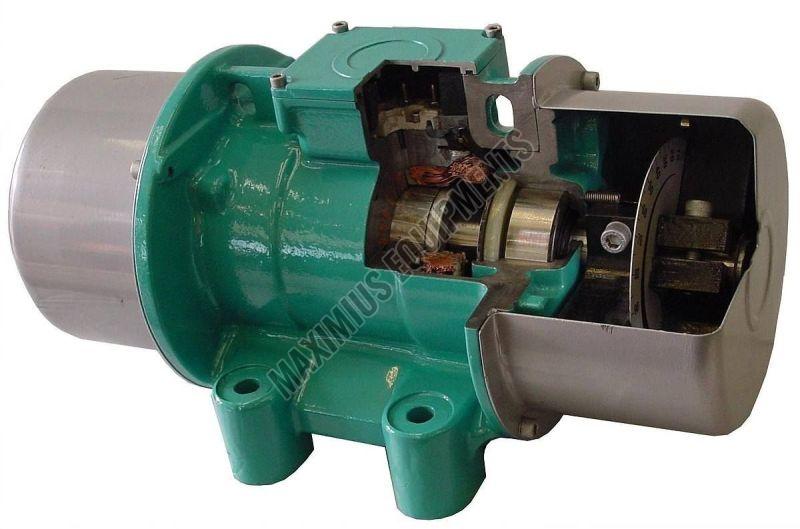

Maximius Unbalance & Vibro Motors are reliable drives for vibration feeder technology and bulk material handling across industries. These three-phase AC induction motors feature flyweights mounted on the shaft ends, generating centrifugal forces adjustable by altering the flyweights. This allows efficient vibration for conveyors, feeders, tables, and hoppers, moving material masses up to 11,000 kg.

With operating torques from 0.1 kg.cm to 2,763 kg.cm and forces up to 119 kN, they deliver linear, circular, or elliptical vibrations, depending on arrangement:

Double counterrotating drives → linear motion (for conveyors/pipes).

Central single drives → circular motion (for feeders).

Offset single drives → elliptical motion (for bunkers/shakers).

Benefits: explosion-proof ATEX zones 21+22, CSA Class 1+2, thermistor protection, compact design, high efficiency, continuous operation, and full EC compliance. Available for 50/60 Hz and various voltages.

Maximius ensures advanced, safe, and durable vibro motor solutions for heavy-duty applications.